Skyline Ointment / Cream Manufacturing Facility

Capacity: 1 Kg - 5000 Kg.

The Skyline

Pharmatech Processing Unit is designed for the production of pharmaceutical

emulsions, suspensions, ointments, creams, and high-end cosmetic formulations.

These applications require the highest standards in mixing technology, precise

control systems, and advanced recipe management.

The system

enables a fully validate production and cleaning process, built with FDA-approved

materials. With global market requirements continually evolving, the

facility offers flexbility, reliability, and universal applicability for a

wide range of product qualities.

APPLICATIONS

Suitable

for manufacturing:- Ointments, Creams, Lotions,

Gels

- Sterile Eye Drops

- Inhalation Liquids

- Toothpaste

- Hair Care Products

- Mascara

- Mayonnaise

- Body Care Products

- Colour Pastes

STANDARD VERSION

- Hemispherical or conical main

vessel with a slow-speed agitator, equipped with inline or bottom-entry

high-shear emulsifier (HSE) for production-scale units.

- Top-entry homogenise for

pilot-scale units.

- Separate wax phase vessel.

- Separate water phase vessel.

- Capability for internal and

external homogenisation.

- Integrated heating and cooling

system with advanced temperature control and safety features.

- Vacuum system for de-aeration

and improved emulsification.

- Working platform provided for

plants above 300 kg capacity.

- Hydraulic lid lifting system

for easy operation and cleaning.

- Electrical control panel for

process management.

OPTIONS

- User-friendly operator

interface with PLC-based control system.

- Multiple automation package

options.

- Load cell system with

integrated dosing unit.

- Wide capacity ranges

from 5 litres to 2000 litres.

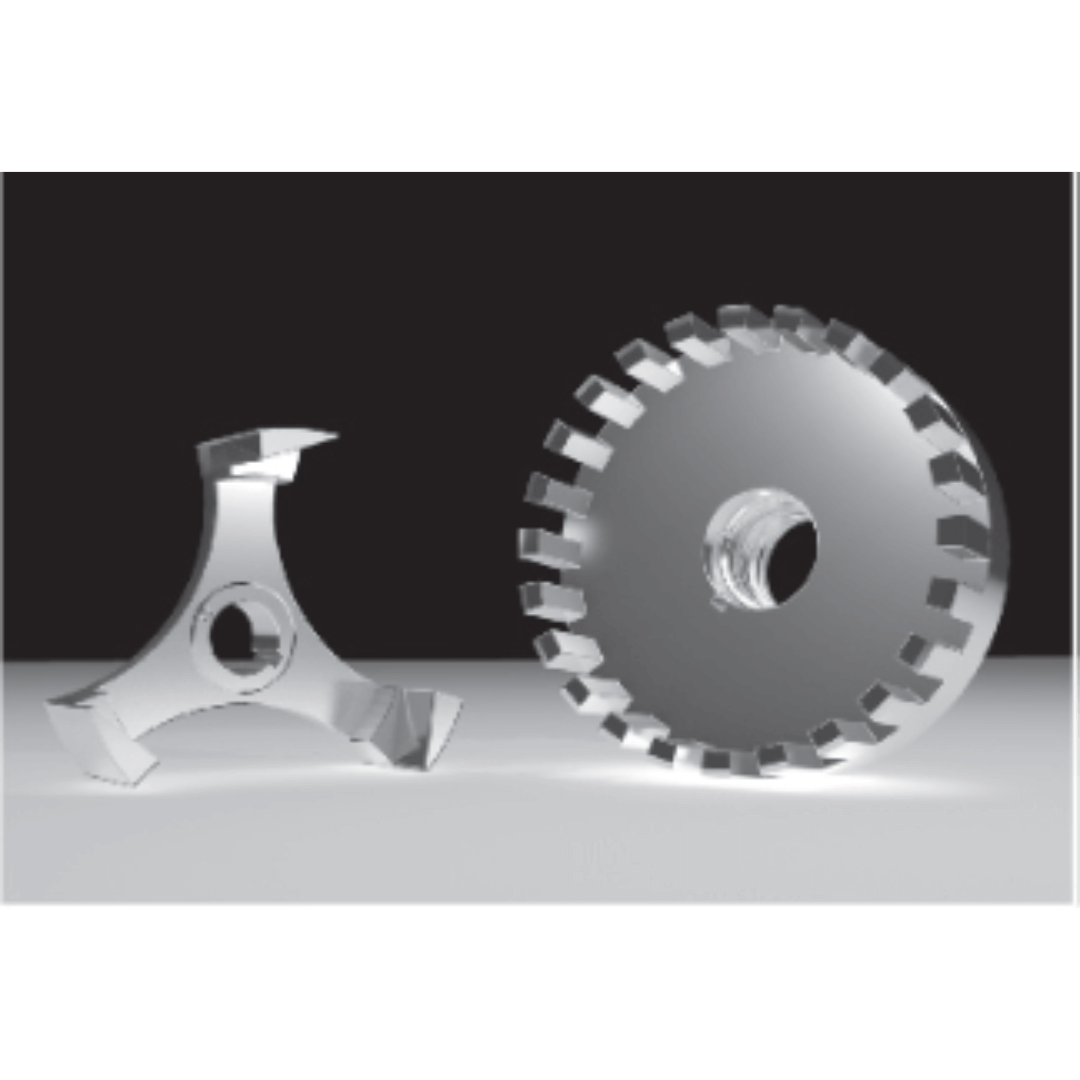

AGITATION & HOMOGENISATION OPTIONS ARE BELOW :

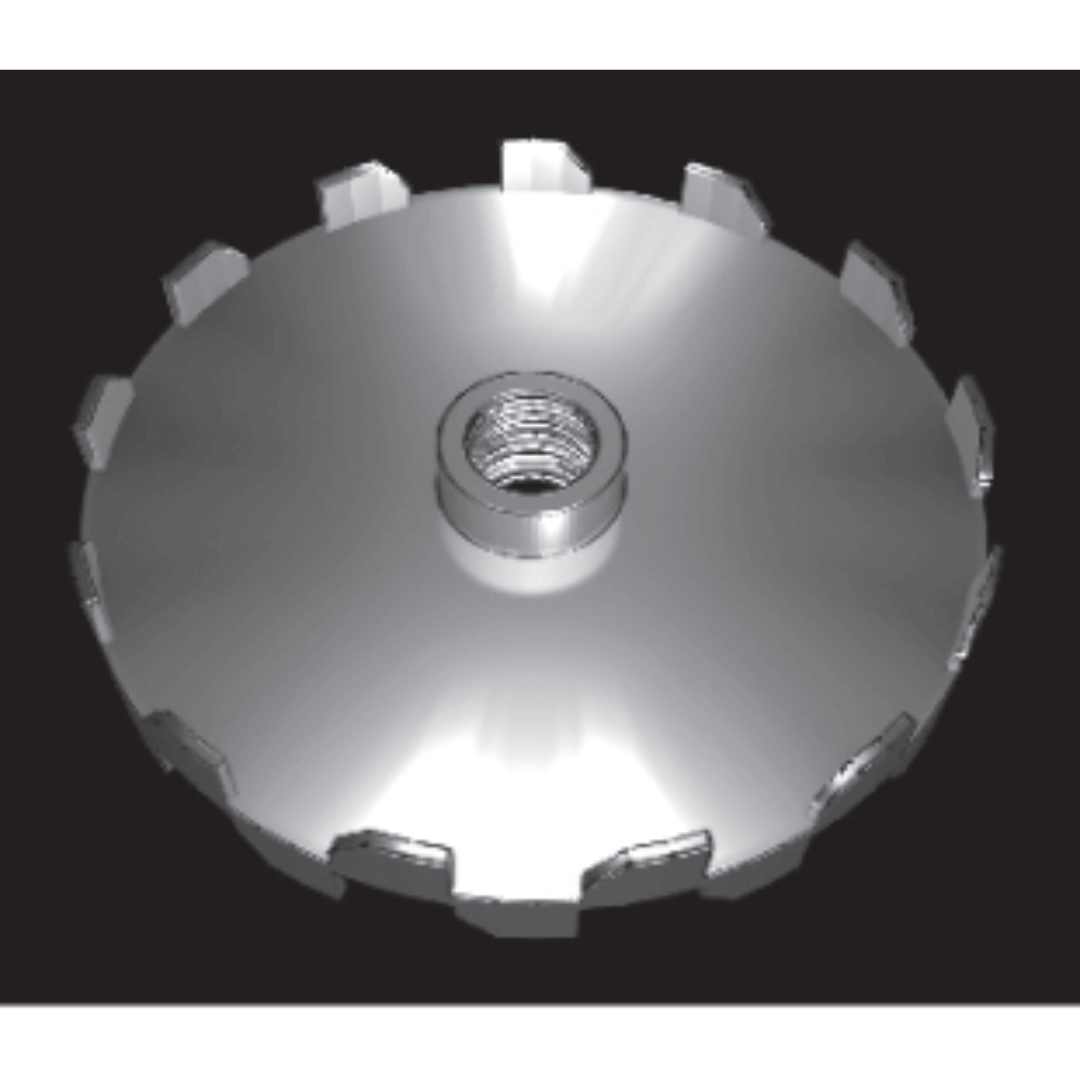

COWL DISC IMPELLER PROPELLER AGITATOR

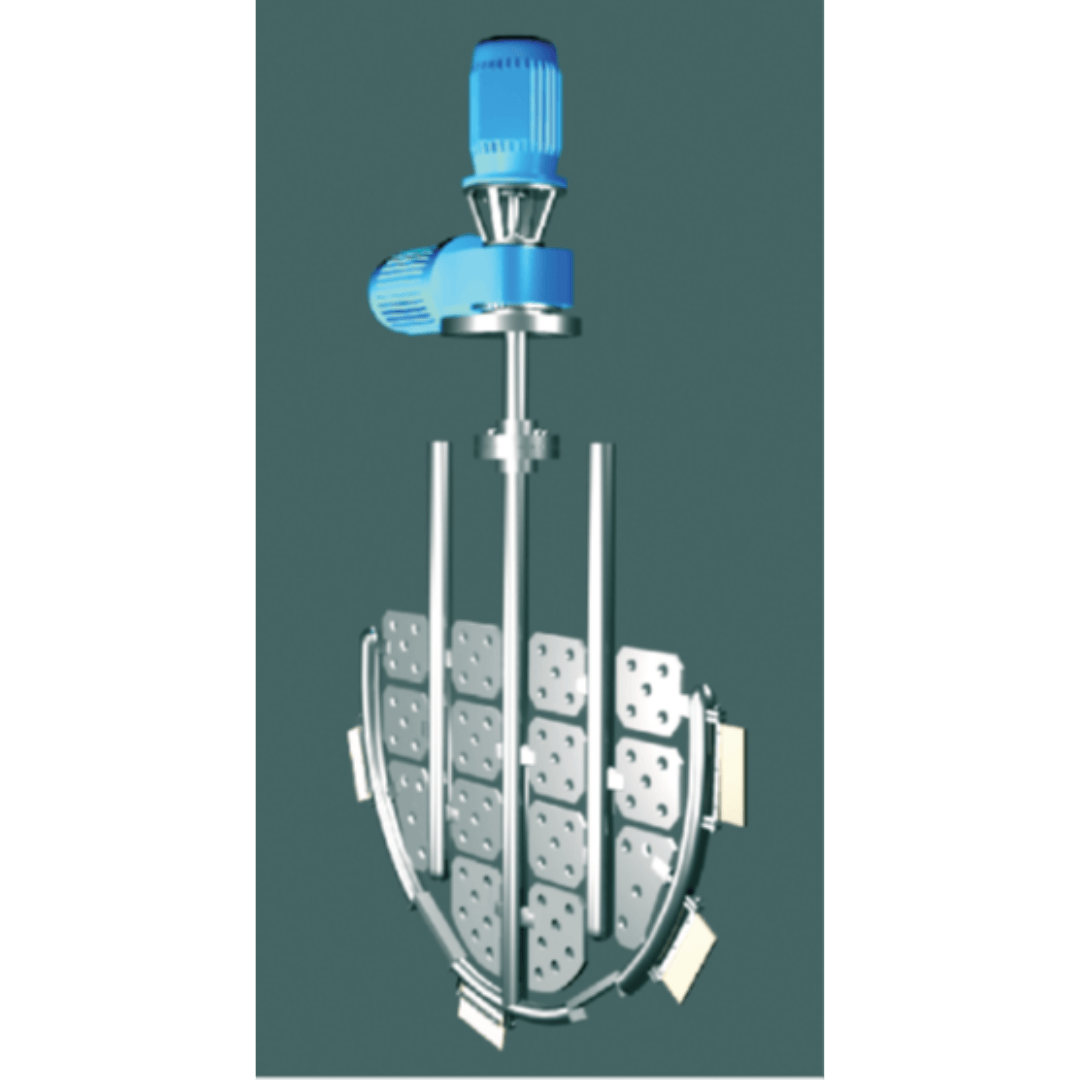

ANCHOR AGITATOR WITH PTFE SCRAPERS

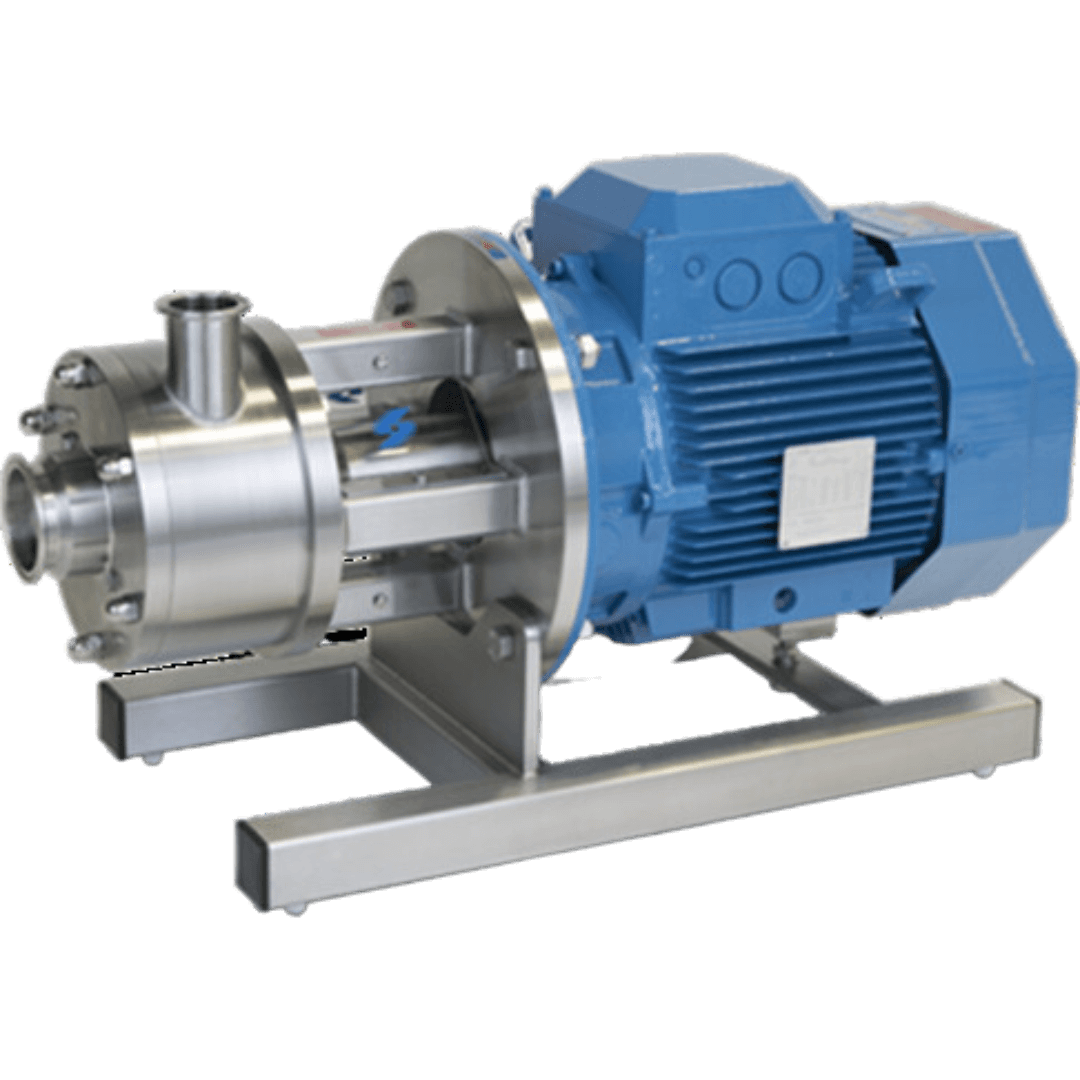

INLINE HOMOGENIZER

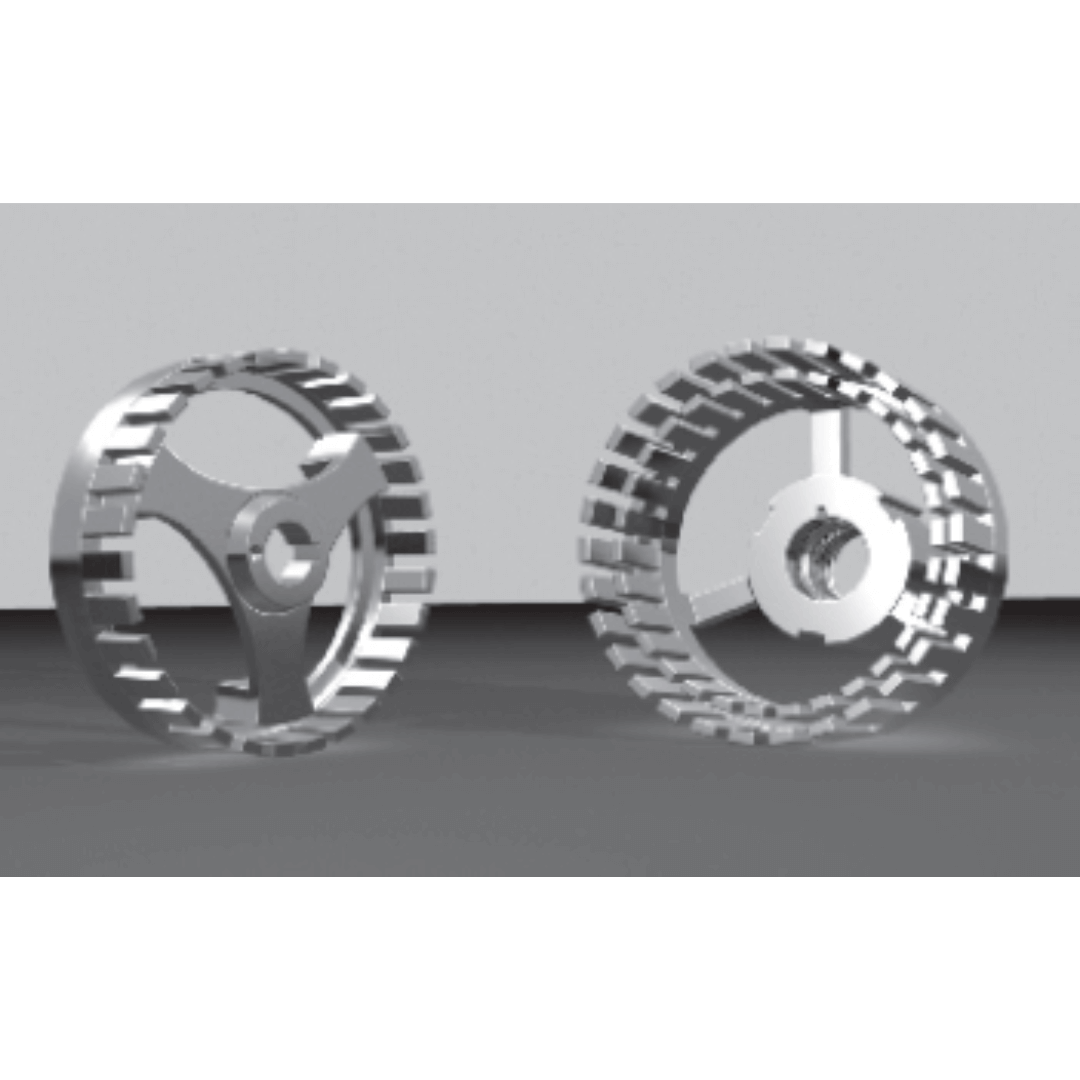

HOMOGENIZER ROTORS